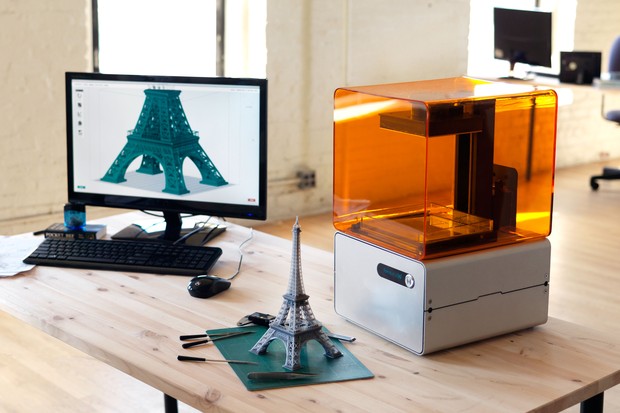

3D Printing has been making quite a stir lately. Regarded as being the start of a new industrial revolution, 3D printing will soon offer the smallest of businesses (and even homeowners) the opportunity to manufacture complicated parts and products affordably from their office.

The process involves converting digital CAD models into physical plastic objects by printing thin layers on top of each other until the digital file is fully replicated in 3D. The advantage of this technology is that intricate and low volume plastic parts can be manufactured cheaply and locally. This is in comparison to processes like injection moulding which have high tooling expenses and labour costs that can only be justified by large production runs.

As 3D Printing technology matures, so too does the reality that this process could be utilized in the manufacture of Point of Sale displays. Selmor Displays has used 3D printing in the past to prototype plastic components for testing before investing in tooling for injection moulding. Today, custom made plastic components that require injection moulding have only been affordable for displays that will be produced in very large quantities. At Selmor Displays we pride ourselves in being able facilitate both large and small production runs. With the use of 3D printing it will soon be possible to offer intricate plastic component displays for smaller quantity orders, while offering competitive pricing.

The Selmor Team