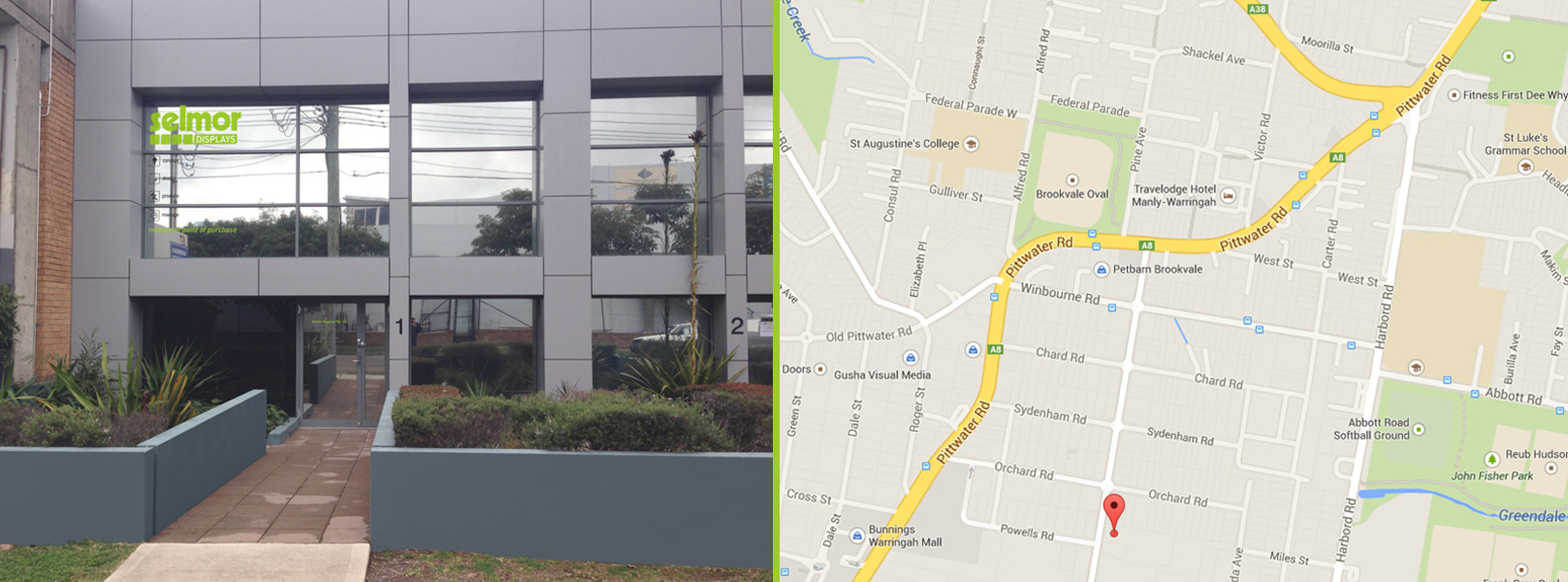

Congrats to the whole team at Selmor Displays for taking home multiple awards at this years inaugural POPAI awards!!

Our Scan & Discover project, in collaboration with Lateral Systems, for the nice people at Super Cheap Auto was recognised by a panel of industry judges in a number of categories. We were awarded:

– SILVER WINNER for Speciality Retail, Lifestyle & Service Providers in Permanent Displays

– GOLD WINNER for Digital In-Store

– and the overall PINNACLE WINNER for Best Shopper Experience

Our continuing work for Nestle Australia and Dolce Gusto was also awarded:

– GOLD WINNER for Consumer Electronics in Permanent Displays